Wibeee to know industrial solar consumption and production

Solar Consumption and Production: All the Data at Your Service and in Real Time

Having real-time information on electricity consumption and solar production is crucial for the energy efficiency of your industry because it allows for more precise and adaptive energy management. With this data, informed decisions can be made to optimize energy use, reduce costs, and minimize environmental impact by adjusting consumption based on solar energy availability, resulting in a more sustainable and economic system.

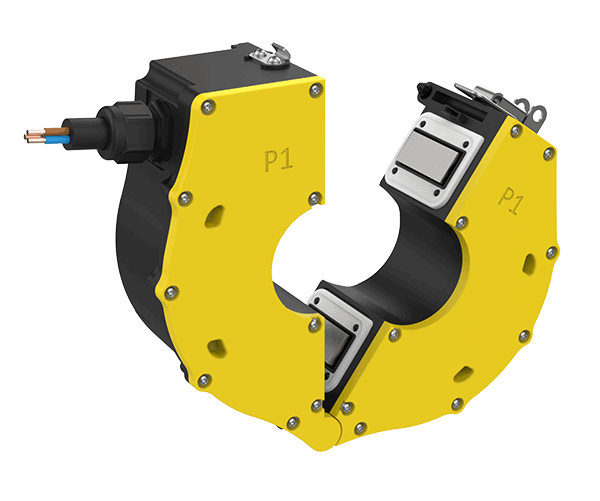

The brand model or configuration don’t matter for the different inverters that you may have installed in your photovoltaic system: for Wibeee this is irrelevant. You will be able to read your production in the second, regardless of the system and how powerful it is. With our range of Max meters, prepared to measure up to 5kA, we are sure that we will cover all your needs.

Oh. And if your installation is years old, and you need a retrofit, Wibeee will prevent you from having to change inverters!

CO2 Footprint, a Fundamental Measure for the Environment… and for Your Industry

Calculating the carbon footprint in industrial production processes is essential to identify the main sources of emissions, comply with environmental regulations and optimize the use of resources. Wibeee provides detailed reports that allow industries to develop effective mitigation strategies and improve their environmental performance, achieving a competitive advantage.

Wibeee, 2Grid and Sensors